BASICS OF PIPE STRESS ANALYSIS: A PRESENTATION -1

Contents

- Objectives of Pipe Stress Analysis

- Governing Codes and Standards

- Stresses in a Piping System

- Reducing Piping Stresses

- Basic Allowable Stress

- Loads on a Piping System

- Work Flow Diagram

- Stress Criticality & Analysis Method

- Piping Stress Analysis using Software Caesar II

- Type of Supports

- Questionnaire

Objectives of Pipe Stress Analysis:

Structural Integrity:

- Design adequacy for the pressure of the carrying fluid.

- Failure against various loading in the life cycle . Limiting stresses below code allowable.

- Limiting nozzle loads of the connected equipment within allowable values.

- Avoiding leakage at joints.

- Limiting sagging & displacement within allowable values.

- Avoiding excessive flexibility and also high loads on supporting structures. Aim towards an optimal design for both piping and structure.

- Codes and Standards specify minimum requirements for safe design and construction (i. e. provides material, design, fabrication, installation and inspection requirements.)

- Following are the codes and standards used for Refinery Piping:

- ASME B31.3: Process piping Code

- ASME B31.1: Power Piping Code

- Centrifugal Pumps: API 610

- Positive Displacement Pumps: API 676

- Centrifugal Compressors: API 617

- Reciprocating Compressors: API 618

- Steam Turbines: NEMA SM23/ API 612

- Air Cooled Heat Exchanger: API 661

- Fired Heaters: API 560

- Flat Bottom Welded Storage Tanks: API 650

- Heat Exchangers: TEMA/ Vendor Specific.

- Vessel/Column: Vendor Specific

- Sources for generation of stress in a Piping System:

- Weight

- Internal/External Pressure

- Temperature change

- Occasional Loads due to wind, seismic disturbances, PSV discharge etc.

- Forces due to Vibration.

- Sustained Stresses are the stresses generated by sustained loads. (e.g. Pressure , Weight). These loads are present continuously throughout plant life.

- Resistive force arising out of sustained stresses balance the external forces keeping the system in equilibrium. Exceeding sustain allowable stress value causes catastrophic failure of the system.

- As per ASME B 31.3, (clause 302.3.5) “ The sum of the longitudinal stresses, SL, in any component in a piping system, due to sustained loads such as pressure and weight, shall not exceed the product Sh x W ”. Where, Sh=Basic allowable stress at maximum metal temperature expected during the displacement cycle and W=weld joint strength reduction factor.

- Pressure Stresses are taken care of by calculating and selecting proper pipe thickness.

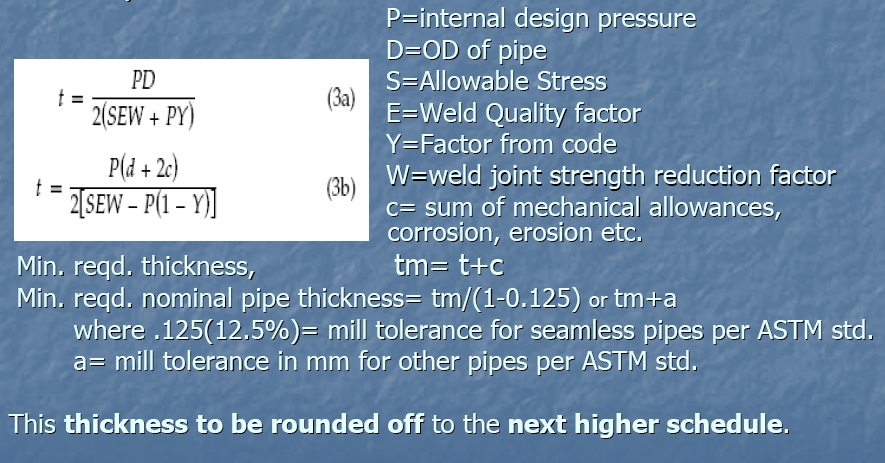

- The pressure thickness (t) of a straight pipe can be obtained as per ASME B31.3 from the equation (Clause 304.1.2) mentioned in Fig.1:

- The pressure thickness (t) of a straight pipe can be obtained as per ASME B31.3 from the equation (Clause 304.1.2) mentioned in Equation for Thickness ASME B 31.3

- Change in length of a pipe of length L due to temp change (ΔT) is given by ΔL=L α ΔT Here, α =Co efficient of thermal expansion = change in length of unit length element due to unit change in temp.

- Two “α” values in Code (Table C1 and C3 in ASME B31.3 Appendix C):

- Table C1 denotes total linear thermal expansion between 700 F to Indicated temp (unit=in/100ft).

- Table C3 denotes mean coefficient of linear thermal expansion between 700 F to indicated temp (μin/in/0F).

- Expansion stresses are generated when the free thermal growth due to temperature change is restricted. These are self limiting or relenting.

- SIF( Stress Intensification Factor): This is the ratio of the maximum stress intensity to the nominal Stress. SIF factors for different components can be obtained from Appendix D of ASME B31.3.

- Displacement Stress Range due to thermal expansion is calculated based on equation SE = ( Sb^2+4 St^2)^0.5 per equation 17 from ASME B31.3( clause 319.4.4).

- This SE value shall not exceed SA value where SA= Allowable Displacement Stress Range.

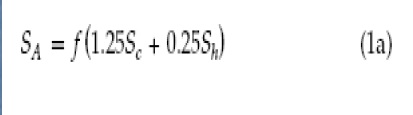

- As per ASME code B 31.3 (Clause 302.3.5) the allowable displacement stress range (SA) can be given by the equation Equation for Displacement Stress Range Allowable

- As per ASME code B 31.3 (Clause 302.3.5) the allowable displacement stress range (SA) can be given by the equation (Fig.2):

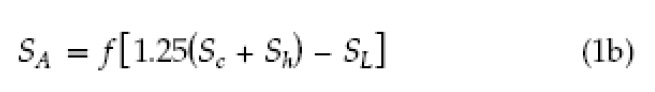

- When Sh > SL , the allowable stress range is calculated by the following equation (Fig. 3): SL=Longitudinal Stress due to sustained loads.

- Occasional Stresses are generated by the occasional loads such as Wind, seismic, PSV discharge etc.

- This loads act in a piping system for very small period of time, usually less than 10% of total working period.

- As per ASME B31.3 clause 302.3.6 “The sum of the longitudinal stresses, SL, due to sustained loads, such as pressure and weight, and of the stresses produced by occasional loads, such as wind or earthquake should be ≤ 1.33 times the basic allowable stress, Sh”

- Code does not explicitly explain the stresses generated due to vibration.

- The vibration problems are solved by engineering judgment and experience.

Optimal Design:

Governing Codes and Standards:

Here, f= Stress range reduction factor and Sc=basic allowable stress at minimum metal temp.

Reducing Piping stresses:

No comments:

Post a Comment